Specialty Components

Specialty Components Designed to Solve Unique Challenges

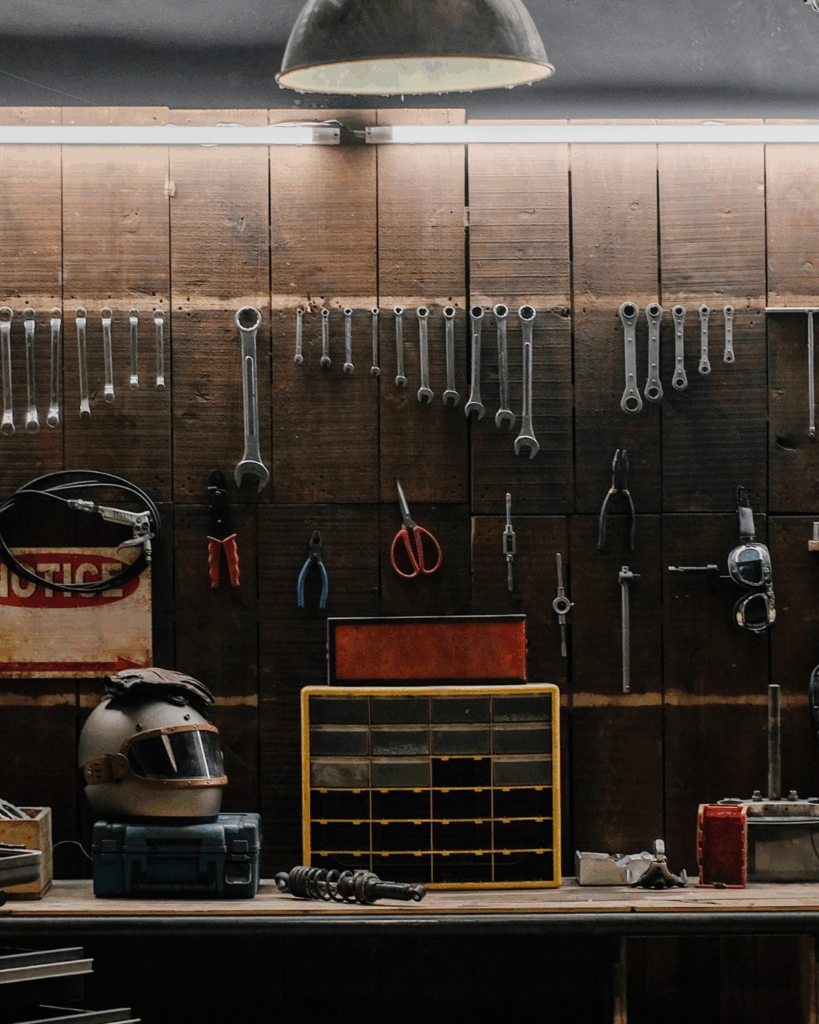

Not every part fits a standard spec — and that’s where Electro-Seal shines. Our specialty machining services are trusted by engineers and OEMs to deliver precision components that don’t come off a shelf.

From legacy replacements to one-off parts and complex assemblies, we manufacture what others can’t — all under one roof at our Indiana facility.

Made-to-Order, Built to Perform

Our specialty components are used in demanding applications across:

Agricultural equipment

Industrial machinery

Power generation

Aerospace systems

Automotive and heavy vehicles

Custom OEM assemblies

Whether you’re trying to replace a discontinued component or develop a part with unique fit, pressure, or durability requirements, we provide end-to-end manufacturing with rapid turnaround.

Common Specialty Products We Manufacture

Liquid Indicators

Precision-machined windows and indicators for fluid-level monitoring systems

OEM Tractor Parts

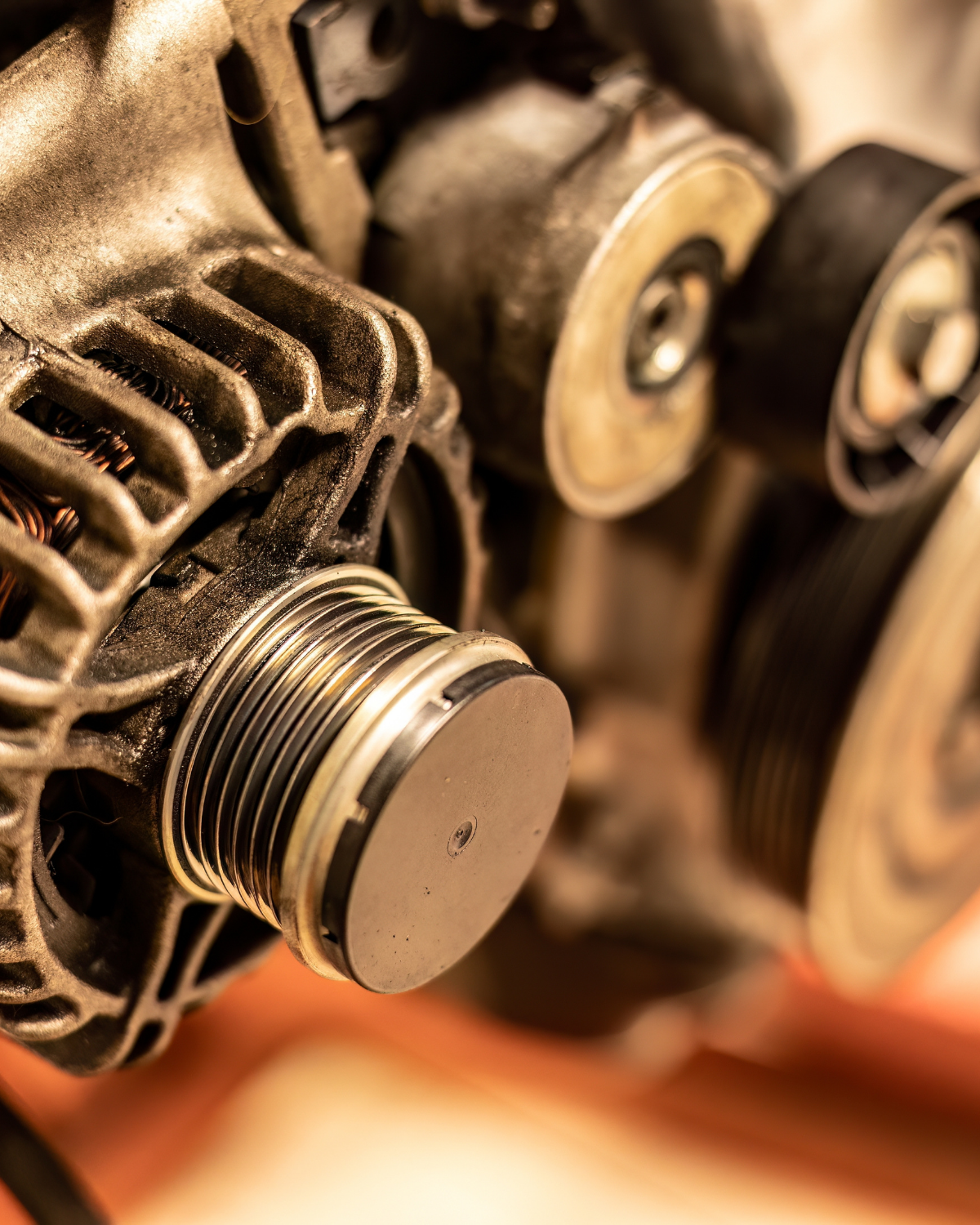

Custom pulleys, mounts, bushings, and drive components

Fasteners & Connectors

Non-standard screws, bolts, and fastening systems

Sealing Components

Machined rings, gaskets, and fittings for pressure vessels

Proprietary Assemblies

Confidential custom work for OEMs in defense, aerospace, and biotech

Glass-to-Metal Components

Unique adaptations of our hermetically sealed product line

Features & Capabilities

Multi-axis CNC and screw machining

Prototyping to high-volume production

Threaded, grooved, and splined parts

Heat-resistant and corrosion-proof finishes

Material options include metals, plastics, and custom alloys

Post-processing: anodizing, plating, heat treating, engraving

No matter how niche the requirement, our team will guide you from concept to final part with full technical support.

End-Use Scenarios

Our specialty components are often found in:

Hydraulic and pneumatic systems

Fuel delivery systems

Sanitary equipment and lines

Custom enclosures or pressure chambers

Complex belt-driven powertrains

Instrumentation systems needing clear observation or high pressure control

We routinely serve industries where standard just won’t do — and where parts must meet regulatory, structural, and environmental challenges.

Why Choose Electro-Seal?

-

Custom Engineering Focus

We're built to create non-standard components

-

Made in the USA

Consistent quality and shorter lead times

-

Single-Run or Repeatable Production

We scale with your needs

-

Problem-Solving Mentality

We collaborate closely with your team to get it right

The Electro-Seal Difference

We understand the challenges of sourcing obscure or custom components. Whether you’re dealing with outdated OEMs, demanding specs, or urgent needs, Electro-Seal offers fast, reliable solutions — and American-made craftsmanship you can count on.

Our customers return to us not just for our machining capabilities, but for our ability to think like engineers and deliver on the first try.

Let’s Build Your Specialty Component

If you need a unique, complex, or high-performance part, we’re here to help. Our team thrives on technical challenges and welcomes projects that require creative, agile thinking.