Built Around Your Specs

Custom Machining ServicesBuilt Around Your Specs

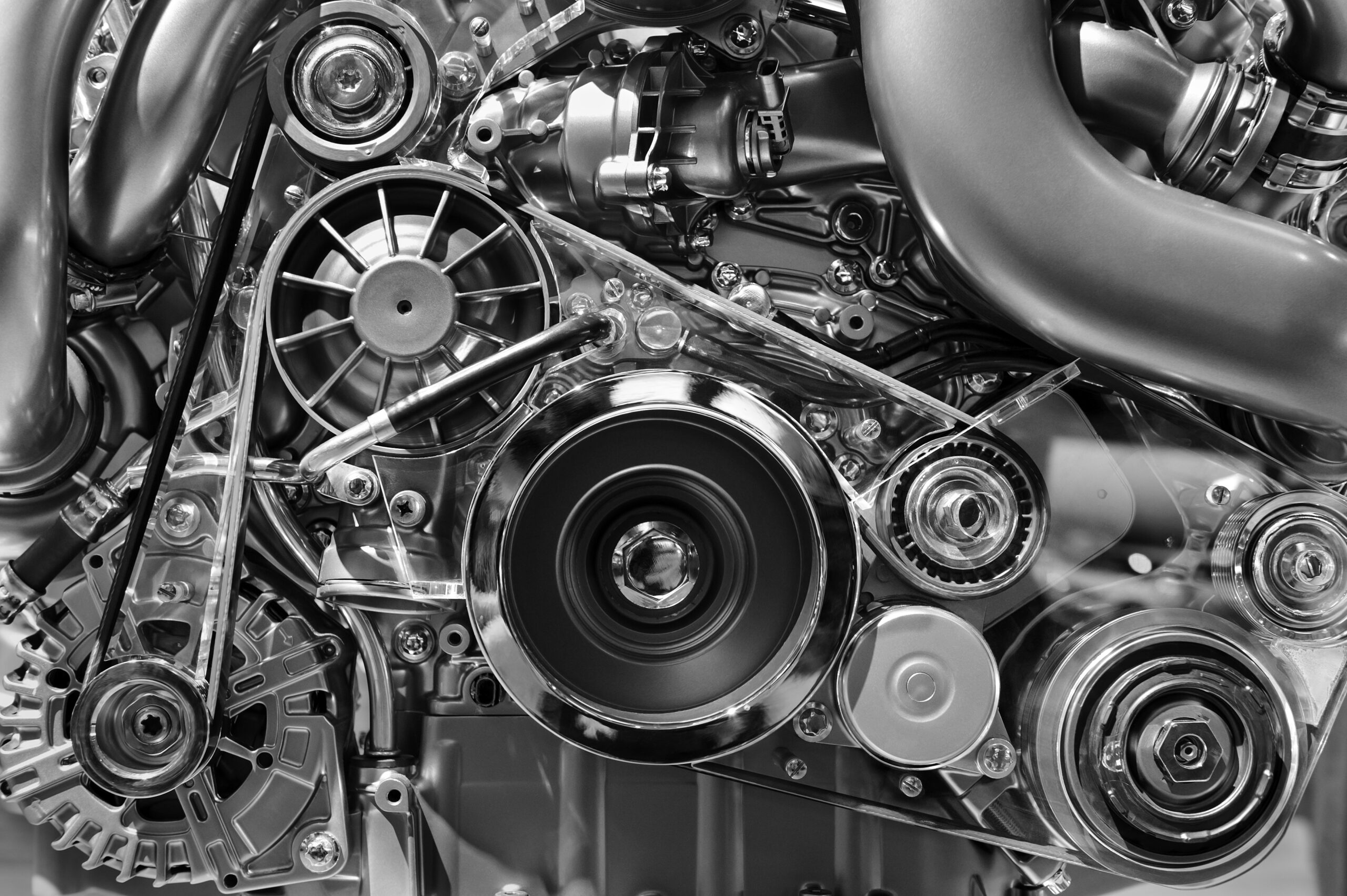

When precision matters and timelines are tight, Electro-Seal delivers. Our custom machining services are designed for manufacturers, engineers, and OEMs who need dependable, made-to-spec components — whether it’s a one-off prototype or a full production run.

From CNC and screw machining to secondary operations like heat treating and coating, we provide a full spectrum of in-house services to take your design from concept to completion.

One Partner. Infinite Possibilities.

Electro-Seal has spent decades fine-tuning our machining capabilities to support complex parts, tight tolerances, and custom materials. We serve clients across industries including automotive, aerospace, oil and gas, food processing, pharmaceuticals, and industrial equipment manufacturing.

We handle jobs others won’t — or can’t.

What We Offer

CNC Machining

High-precision turning, milling, drilling, and tapping on a wide variety of metals and plastics. Ideal for tight-tolerance and geometrically complex parts.

Screw Machining

Multi- and single-spindle screw machines enable efficient production of small-to-medium-sized components in high volumes or custom configurations.

Prototyping

Rapid prototyping for concept testing, validation, and fit/form/function evaluation before full-scale production.

Small Lot & Short Runs

No need to meet high minimums — we specialize in limited-volume production with consistent quality and fast turnaround.

Secondary Operations

Heat Treating | Deburring | Engraving | Plating & Coating | Threading & Finishing

We Machine a Wide Range of Materials

Our facility is equipped to work with:

Stainless steel

Brass

Carbon steel

Aluminum

Copper alloys

Plastics (Delrin, Nylon, PTFE, etc.)

Specialty alloys based on your spec sheet

Whether it’s strength, conductivity, heat resistance, or corrosion protection — we select and process the right material for your project’s performance needs.

Our Process

We keep your job on track with a proven, transparent workflow:

01 Collaborate

Share a drawing, model, or concept; our team reviews specs and materials

02 Quote

We provide a clear estimate, including timelines and tolerances

03 Machine

Parts are produced in-house using our CNC lathes, mills, or screw machines

04 Inspect

Every part is checked for conformance before shipping

05 Deliver

On-time, every time — shipped nationwide

Who We Serve

Our custom machining customers include:

OEMs in need of proprietary parts

MRO departments with emergency or legacy part needs

Engineers designing prototypes or testing new designs

Product developers scaling up for production

Distributors sourcing specialized or hard-to-find parts

Whether you’re launching a new design or replacing a discontinued component, Electro-Seal brings speed, flexibility, and American-made quality to your manufacturing needs.

Why Choose Electro-Seal?

Decades of machining expertise

Flexible volumes with no minimums

Made in the USA — in-house control from start to finish

Responsive service and engineering support

Short lead times and fast prototyping

Ready to Get Started?

Whether you have a complete technical drawing or just a sketch and a goal, Electro-Seal is ready to help you build the perfect part — fast, affordable, and on spec.