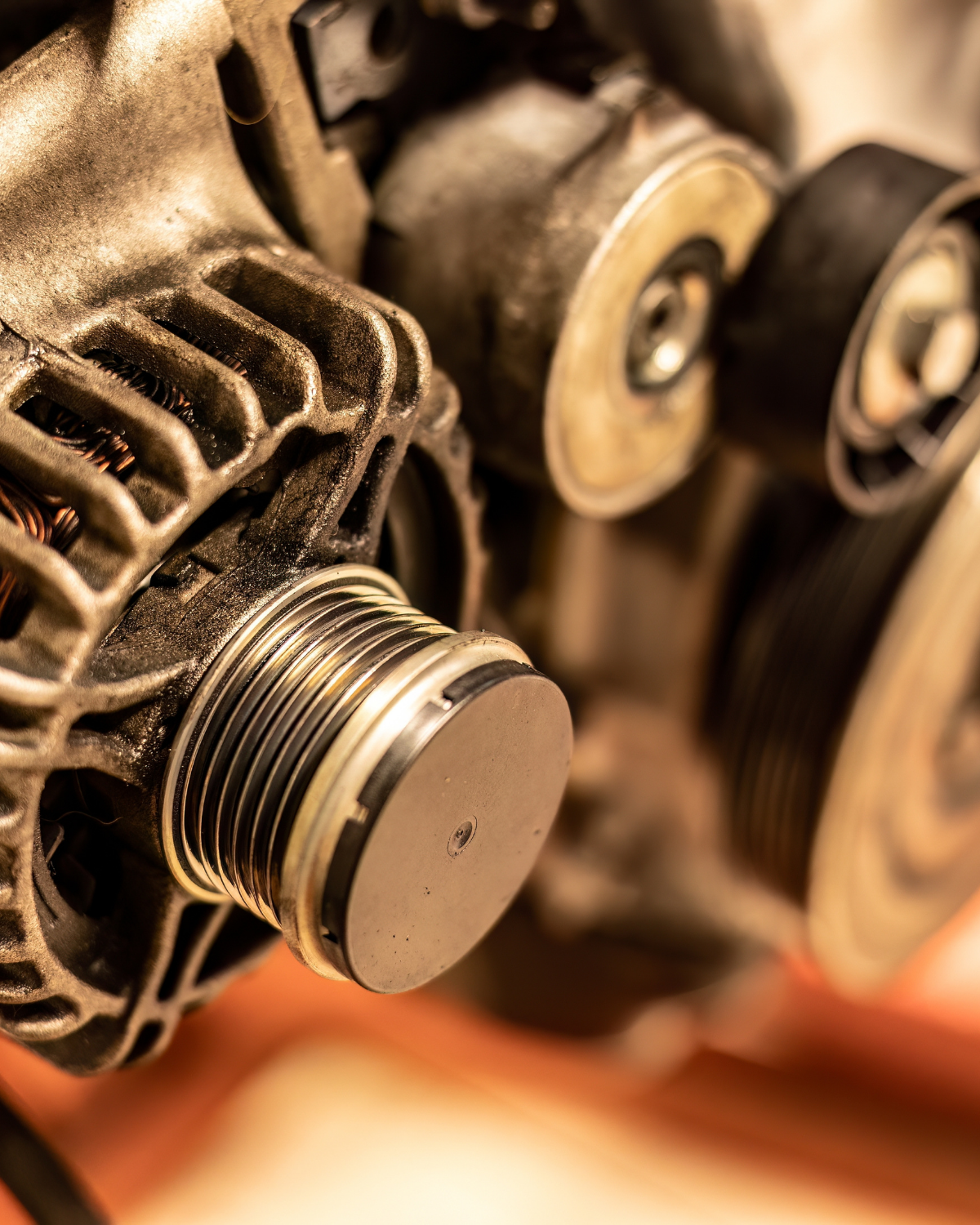

Alternator Pulley Components

Precision AlternatorPulley Components Engineered to Perform

When performance matters, Electro-Seal delivers. With more than 375 unique alternator pulley models in production, we’re a trusted manufacturing partner for OEMs, rebuilders, and aftermarket distributors across North America.

Whether you’re servicing aging equipment or designing a new power system, our precision-machined pulley components offer the reliability, fit, and performance your application demands.

Built to OEM Standards — and Then Some

Our alternator pulley components are manufactured using high-grade materials and tight-tolerance machining techniques to ensure long-lasting performance and seamless integration.

Each pulley is made to exacting OEM specifications or can be customized for unique alternator configurations, including:

Standard and custom diameters

Multiple groove profiles

V-belt and serpentine belt compatibility

Keyways, set screws, or custom bore features

Aerospace & Marine Applications

Balancing and concentricity checks

We produce both low- and high-volume orders with equal attention to detail and quality control.

Trusted by Multiple Industries

Electro-Seal pulley components are used in a wide range of systems where belt-driven performance is essential. We serve manufacturers, suppliers, and equipment rebuilders in:

Light-duty and heavy-duty vehicles

Tractors, harvesters, generators

Loaders, compactors, hydraulic systems

Power units, compressors, auxiliary systems

Direct-fit parts for a wide range of alternator models

Whether your product is under the hood, in the field, or on the factory floor — our pulleys are built to keep things moving.

Why Electro-Seal for Pulley Manufacturing?

Over 375 Existing Models

A massive catalog of pulley designs ready to go

Custom Engineering

We build to your blueprint, or reverse-engineer from existing parts

Made in the USA

Every pulley is manufactured at our Indiana facility

Scalable Production

One-off replacements or recurring high-volume orders

Fully Inspected

Dimensional checks, concentricity, and performance validation

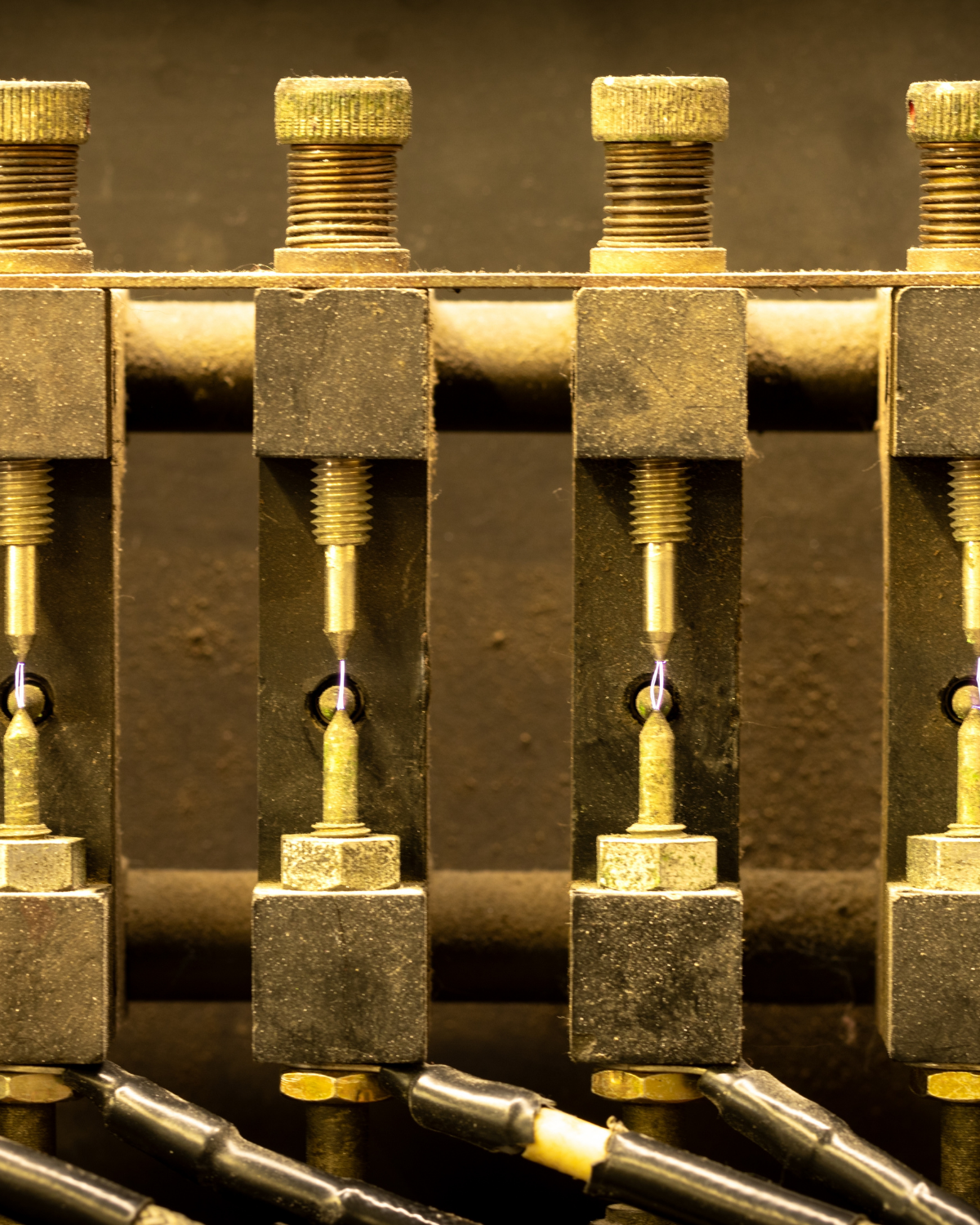

Pulley Materials & Finishes

We machine pulley components using a range of durable, performance-tested materials including:

Steel

Stainless Steel

Aluminum

Brass

Coated or plated finishes for corrosion resistance

Additional services such as heat treating, balancing, anodizing, or custom engraving are available to match your technical or branding requirements.

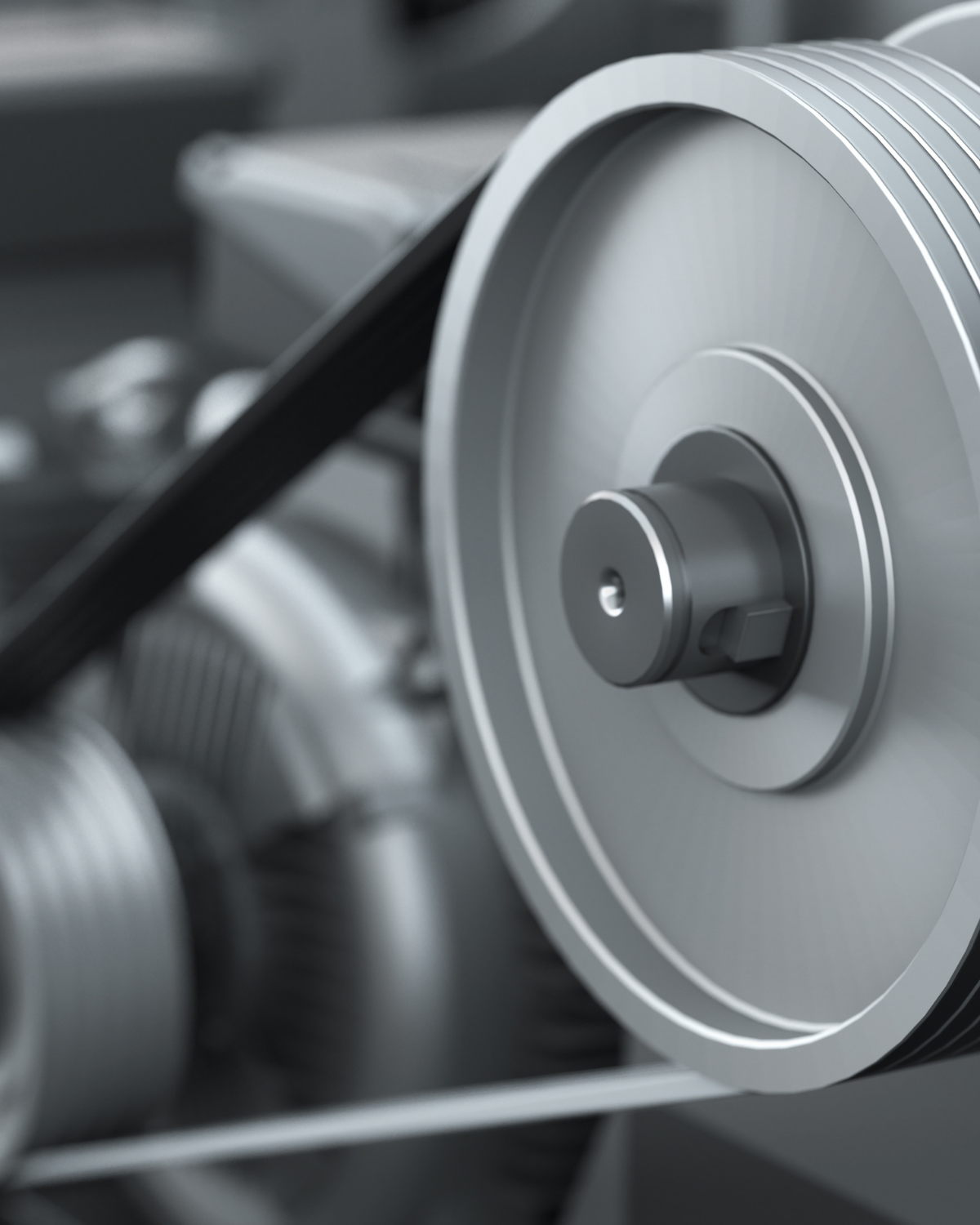

Sample Applications

Some of the most common alternator pulley types we manufacture include:

Fixed and adjustable pulleys

Multi-groove pulleys

Tapered bore pulleys

Splined shaft pulleys

Specialty fasteners and bushings

If you don’t see the part you need, we can make it — even for discontinued or proprietary systems.

Streamline Your Supply Chain

With Electro-Seal as your pulley manufacturing partner, you gain:

A reliable U.S. source for alternator components

The ability to scale production based on market needs

On-time delivery and responsive service

Reduced lead times and higher quality consistency

Whether you’re an OEM, Tier 1 supplier, or parts distributor, we’re here to ensure you get the pulleys you need — built right the first time.

Let’s Get Your Project in Motion

Need a quote for OEM pulley components or a custom alternator pulley configuration? Our team is ready to help. From drawings to finished parts, we manage every step in-house to ensure exceptional quality and turnaround time.